還在為工件表面處理的問題發(fā)愁嗎���?看看這里��。

QPQ是什么? What is QPQ�����?

“QPQ”是英文“Quench—Polish-Quench”的縮寫�����。原意為淬火一拋光一淬火����。QPQ技術是冶金學領域內帶有革命的新技術,它是在兩種不同性質的鹽浴中使金屬表面滲入多種元素��,同時使其耐磨性和抗蝕性比常規(guī)熱處理和表面防腐技術成倍的提高�����。

QPQ is“Quench-Polish-Quench”for short in English. QPQ technology is a new revolution technology in the field of metallurgy. It seeps a variety of metal elements to the surface in the two different nature of the bath. By QPQ treatment, the wear resistance and anti-corrosion resistance of workpiece are exponentially increased than conventional heat treatment.

經QPQ處理后有什么不一樣? What is the Distinguishing Feature of QPQ?

1. 極高的耐磨性���、良好的耐疲勞性 Extremely high wear resistance and good fatigue resistance

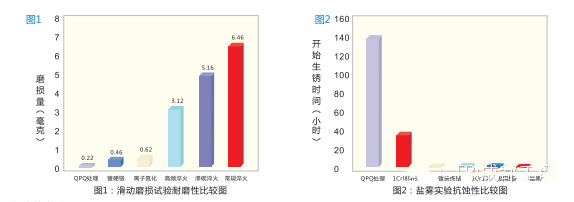

根據(jù)滑動磨損實驗的結果���,QPQ處理后���,中碳鋼的耐磨性可達到常規(guī)淬火的30倍,低碳鋼的耐磨性是滲碳淬火處理的14倍�����,是離子氮化處理的2.8倍�,是鍍硬鉻處理的2.1倍�。QPQ處理后中碳鋼的疲勞度可以提高40%以上(圖1)。滾動磨損實驗的結果大體相似�。

According to the result of slid-wear testing, the wear resistance of medium carbon steel with QPQ treatment is 30 times than conventional quenching. The wear resistance of low carbon steel with QPQ treatment is 14 times than cemented quenching, is 2.8 times than ion nitriding, and is 2.1 times than plating hard chromium. Resistance to fatigue of medium carbon steel can be increased by more than 40%(pic.1). The results of rolling wear experiment is generally similar to slid-wear testing.

2. 極好的抗蝕性 Excellent corrosion resistance

中碳鋼經QPQ處理后,在鹽霧中的抗蝕性為鍍硬鉻的70倍�����,鍍裝飾鉻的35倍��,比1Crl8Ni9Ti不銹鋼還高5倍����。工件大氣存放實驗和硫酸銅浸蝕實驗都表明,經QPQ技術處理后鋼件具有極高的抗蝕性(圖2)��。

The corrosion resistance of carbon steel, by QPQ treatment, is 70 times than hard chromium plating in salt fog,is 35 times than decorative chromium plating, and is 5 times than that of 1Cr18Ni9Ti stainless steel. Both workpiece atmosphere storage experiment and copper sulfate erosion experiment show that steel parts are of high corrosion resistance by QPQ treatment(Pic.2).

3. 極小的變形 Minimal Deformation

QPQ處理后工件幾乎不變形�����,是變形最小的硬化技術���?��?梢越鉀Q常規(guī)硬化方法無法解決的硬化變形難題?����?梢蕴娲慊穑ǜ哳l淬火����,滲碳淬火)——回火——發(fā)黑(鍍鉻)等多道熱處理和防腐工序。采用QPQ技術可大大縮短生產周期�,降低生產成本。

QPQ is minimal deformation hardening technology, which makes no deformation for the work pieces . It is used to solve the deformation problem which cannot be solved by conventional methods . As well as it can replace quenching (high-frequency quenching, carburizing quenching) - tempered - black (chrome plated) processings. QPQ technology can greatly shorten the production time and reduce the cost of production.

4. 無公害化水平高�,不污染環(huán)境 Non-environmental Pollution

經有關環(huán)保部門監(jiān)測鑒定,各種有害物質排放量均遠低于國家排放標準允許值�。

Identified by environmental protection departments, all kinds of harmful substances emissions are lower than the national standard.

第二代QPQ技術 The Second Generation QPQ Technology

我公司的第二代QPQ技術使碳鋼化合物層厚度可達到30μm以上,達到了國內領先水平。利用電流催滲加快滲層的形成速度等方法���,研究開發(fā)出的第三代QPQ技術(即超深層QPQ技術)可使碳鋼化合物層厚度達到60μm以上�����。本技術是擁有完全自主知識產權的獨創(chuàng)新技術��,達到國際先進水平�。

The second generation QPQ technology of CTRI enable carbon compound layer thickness reach to more than 30μm, which is the leading level in China. The third generation of QPQ technology(namely ultra deep layer QPQ Technology), makes the thickness of carbon steel compound layer reach to 60 μm or even more by accelerating the formation of permeation layer. It is a unique technology with full independent intellectual property rights in the international advanced level.

哪些產品可經QPQ處理 Can Be Processed Products

汽車零配件 Auto Parts

曲軸����、凸輪軸���、氣門���、氣彈簧活塞桿、減震器活塞桿��、活塞環(huán)����、齒輪、連桿等

bent axle,camshaft�����, air valve��,Gas spring piston rod����,piston ring,wheel gear����,connecting rod etc.

石油機械 Petroleum Machinery

充氮接頭、心軸�����、連接爪��、球閥外筒�、球座、球閥����、油室活塞��、閘板��、浮閥閥芯�、閥瓣等

nitrogen gas charging fitting����,mandrel,dog coupling���,The external ball valve����,ball seat��,The oil chamber of piston���,flashboard,F(xiàn)loating valve core���,valve clack etc.

液壓系統(tǒng)部件 Fluid power systems and components

閥桿�、閥門��、缸套、活塞桿��、閥座���、液壓機械部件等

valve rod�����,valve����,cylinder jacket��,piston rod�����,valve seat�,Hydraulic Machinery Parts etc.

工模具 Industrial Moulds

鉆頭、絲錐����、拉刀、銼刀����、刀體�����、刀桿���;玻璃模具、橡膠模具����、塑料模具等

drill,screw tap�,broach,file���,cutter body��,holder���,glass mold�,rubber mold,

Plastic mould etc.

紡織機械零部件 Textile Machinery Component

熱軌�����、冷軌、羅拉�、扣片、鋼片縱����、鋼領圈等

Hot-rolling, Cold-rolling�, roller, cramp�����,longitudinal steel sheet���,steel collar etc.